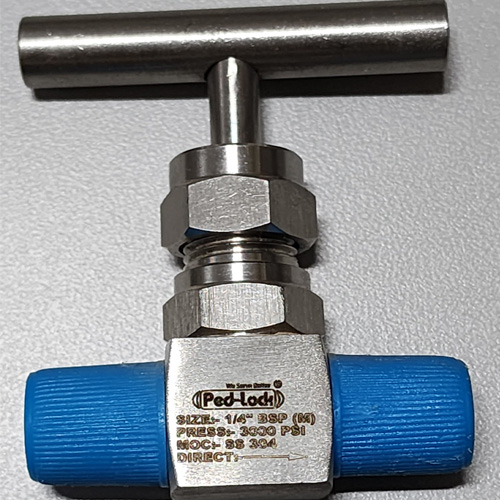

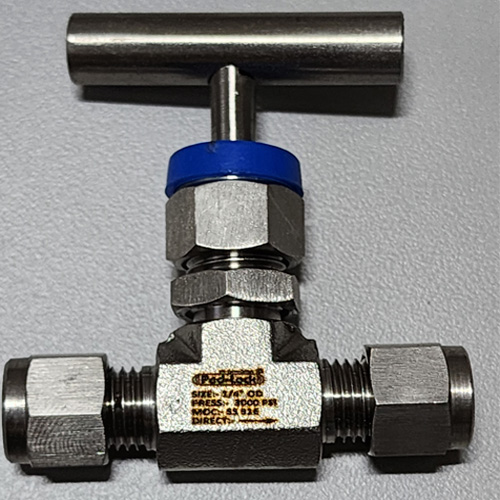

One kind of valve used to regulate the flow of fluid or gas in a system is the needle valve. Its plunger, which like a thin, pointed needle and fits into a conical seat, gives rise to the term. The plunger can be adjusted to alter the size of the the opening through which the fluid or gas travels by turning the stem. The flow rate may be controlled efficiently and precisely by employing this setup.

Many industries, including oil and gas, chemical processing, pharmaceuticals, and instrumentation, frequently employ needle valves. They are frequently employed in situations that need for accurate flow control, such as limiting the flow of gases in the laboratory or changing the flow of liquid in process management systems.